Manufacture of machinery for the dairy and food industry in Italy

Inox Arte has always been involved in the manufacture and installation of machinery and equipment for the dairy industry, especially dairy plants for the production of all kinds of stringy cheeses such as, for example, mozzarella.

Inox Arte plants are safe and reliable and best summarize the advantages of industrial standardization with the love and control of artisanal processing. The experience gained over the years has enabled Inox Arte to become a national leader in the spun-curd cheese industry.

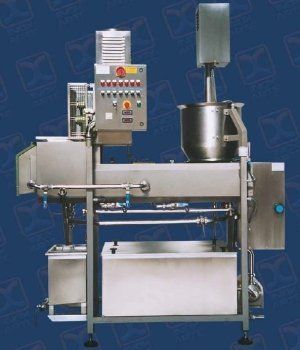

New production line BURRATE

Consisting of the MIRP tilting kneader, MPS 500 fraying machine and volumetric dosing machine.

Spinning machine-form. FFC/2000 Uniblock

The continuous spinning and molding unit mod. FFC/2000 Uniblock was designed and constructed for processing dairy-derived pastes by the combined use in series of:

- a curd-cutting machine, adapted to slice the curd blocks introduced manually into the hopper and cut by four adjustable blades mounted on a disk;

- a stretching machine apt to amalgamate in the processing vat the curd coming from the curd cutter, subjected to continuous humidification by inputting hot water, and conveyed by two intersecting augers at variable speed to the stretching section where two variable-speed plunging arms act to give the product a spinning and the right degree of moisture for any type of processing;

- a forming machine suitable for shaping and operating a constant product size.

Spinning machine-form. FFC/500 Uniblock

Compact unit: cutting, spinning and forming.

Production up to 400 kg/h.

Suitable for the production of: mozzarella, bocconcini, trecce and provole.

Constructed of AISI.304 stainless steel. All parts in contact with the product are coated with TEFLON DU-POINT, sintered at high temperature.

The unit consists of:

- Circular pasta cutter, mounted on the machine, tilting back on itself for washing operation.

- Auger compartment (curd cooking) consisting of double chamber for temperature maintenance and double counter-rotating augers.

- Dough compartment (spinning) equipped with plunging arm system. The machine is equipped with: hot water preparer, with automatic operation that provides for the production and supply of water needed for processing. Direct steam heating system, with silencers.

- Moulder applied to the kneading compartment of the spinner, forming a single body with it. Equipped with No. 02 counter-rotating augers and chamber heated by electric resistance, regulated by electronic temperature controller.

Spinning machine-form. Mod. Ffd/150

Discontinuous spinning and moulding unit, designed for small companies, with artisanal processing. Suitable for the production of mozzarella from 5 to 500 g, braids, plaits, scamorze, provole. Made entirely of AISI.304 stainless steel and food-grade plastic materials.

Composed of:

- Dough cutter with adjustable blades, mounted on the dough compartment;

- dough compartment with plunging arm system with speed variator;

- forming machine applied to the stretcher and forming a single body with it;

IA/95 v150 continuous spinning machine

The spinning machine mod. IA/95 is designed and built for the continuous production of pasta filata starting from the curd properly sliced by the pasta cutter, then it is collected in the processing tank and conveyed by two intersecting augers to the spinning section.

To keep the temperature of the spinning water constant, the machine has an insulated tank filled with appropriately heated water.

Forming machine IA/91

The moulding machine mod. IA/91 is a machine designed for large dairies ideal for production of pasta filata products such as: mozzarella, fiordilatte, provola, trecce, nodini. It can mount accessories such as: molds with sizes from 2 - to 600g and extruder mold for braids and nodini.

The machine can be fed by hand-loaded dough or by tilting mixers directly into the molding machine. Inclination of the machine set in-house.

Made entirely of AISI/304 stainless steel, all parts in contact with the product are coated with TEFLON DU POINT non-stick material.

Forming machine IA/45 RP

The moulding machine mod. IA/45 RP is a machine designed for medium-sized dairies ideal for production of pasta filata products such as: mozzarella, fiordilatte, provole, trecce, nodini. It can mount accessories such as: molds with sizes from 2 - to 600g and extruder mold for braids and nodini.

The machine can be fed by hand-loaded dough or by tilting mixers directly into the molding machine. The inclination of the machine makes it possible to obtain a soft product with a high moisture content.

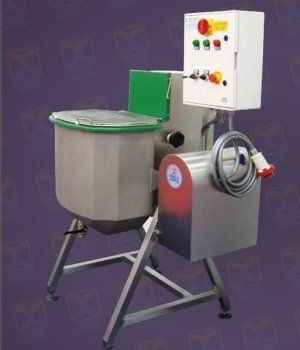

Used IA/12 R30C kneading machine

The kneading machine mod. IA12/ R30C was designed and built for processing dairy-derived dough by means of two opposing rotating reels at variable speed.

The dough is subjected to continuous humidification by the introduction of hot water until it forms a soft, homogeneous paste that is essential for the production of mozzarella, scamorze, provoloni, and caciocavalli cheeses.

Pasta cutting machines IA/10 - IA/11 - IA/11p

The Mod. IA/10 curd-cutting machine was designed and built for cutting curds intended for the production of pasta filata cheeses. The curd blocks are fed into the cylindrical hopper divided into two sections, and are cut by four adjustable blades so as to obtain slices of the desired thickness. For the recovery of the cut product, a collection tub must be placed under the conveyor.

Request a quote

TF 35 automatic spinning machine

The spinning machine mod. TF/35 is a machine designed for the discontinuous production of pasta filata, starting from appropriately minced curds and introduced into the dough compartment.

Where two plunging arms act to give the product a homogeneous stretching, with a desired degree of moisture.

FVA/40 Fuser - FRPA

The moulding spinning and moulding unit mod. FVA40 - FRPA is designed for spinning and moulding fresh or frozen dairy-derived pasta for the production of mozzarella, fiordilatte, provola, trecce, nodini, etc., by means of the combined aid in series of:

a spinning machine suitable for spinning the curd introduced in blocks or sliced into the processing vat is subjected to continuous humidification by joint input of water and steam. The curd introduced into the compartment is processed by two intersecting augers at variable speed with direction of rotation independent of each other so that they both advance forward or backward or opposite to each other, giving the product a spinning and the right degree of moisture for any type of processing

Hot water preparer PV/300

The hot water preparer mod. PV/300 is designed and constructed exclusively for continuous-cycle production of hot water, at variable temperature according to one's business needs, up to a maximum operating temperature of 90 C.

Heating is by means of closed-circuit steam circulation, in the cavity formed by TRAPCOLD type plates, by means of steam flow regulating solenoid valve with temperature controller.All parts of the machine are made of AISI/304 stainless steel, to meet the strictest food and hygiene regulations guaranteed by easy cleaning of parts. Thermally insulated by a rock wool mat, on the cylindrical part of the tank, and externally lined with finely satin-finished or flashed stainless steel.

Cottage cheese production boiler

The cottage cheese production boiler is designed and built exclusively for cooking milk and whey for cheese and cottage cheese production in general. They are insulated vessels with double heating sections using superheated steam, equipped with a drainage system to discharge water produced by steam condensation. Heating of the food product is done by acting through one or both heating sections depending on the quantity introduced. It can also be used as a batch pasteurizer and equipped with temperature control instrumentation.

The machine was built entirely of AISI/304 stainless steel to meet the most stringent food and hygiene regulations guaranteed by the easy cleaning of the surfaces.

Multi-purpose tubs on load-bearing structure

Multipurpose Vats, manufactured by Inox Arte, are designed and built for processing cow's and sheep and goat's milk intended for curds for pasta filata or cheese in general.

Request a quote

They are made of AISI/304 stainless steel with a vertical cylindrical shape, mounted on a supporting structure equipped with adjustable feet for leveling. Access ladder with protective railing.